SARASOTA, FLA.—Hotel industry veteran Richard Ferrell, President of Pürlin, LLC, is aiming to revolutionize how sheets and pillow cases are managed in hotels across the United States. His company’s linens are not laundered; instead, after being used by a guest they are picked up to be 100 percent recycled. Made of high-quality microfibers designed to simulate cotton—the same as those used in products such as baby diapers and athletic wear—the sheets and pillowcases are produced and recycled by companies based in Florida and North Carolina. Once heated to 500+ degrees Fahrenheit, the linens are liquefied and become the ingredients for making brand new sheets, pillowcases and duvet covers, thus resulting in zero waste.

SARASOTA, FLA.—Hotel industry veteran Richard Ferrell, President of Pürlin, LLC, is aiming to revolutionize how sheets and pillow cases are managed in hotels across the United States. His company’s linens are not laundered; instead, after being used by a guest they are picked up to be 100 percent recycled. Made of high-quality microfibers designed to simulate cotton—the same as those used in products such as baby diapers and athletic wear—the sheets and pillowcases are produced and recycled by companies based in Florida and North Carolina. Once heated to 500+ degrees Fahrenheit, the linens are liquefied and become the ingredients for making brand new sheets, pillowcases and duvet covers, thus resulting in zero waste.

“This will forever change hotel laundry,” Ferrell says. “You will never sleep on a sheet or pillow case that anyone has ever used. It is a paradigm shift that will change the way hoteliers and travelers think about bed linens.”

In a typical laundry operation, the quality of cotton-based sheets and pillow cases is diminished over time as laundry detergent, bleaches and other chemicals break down the cellulosic fibers. Stains from women’s makeup can also cause laundering issues resulting in the disposal of the damaged item.

Each Pürlin® sheet and pillowcase is hypoallergenic and saves water—selling points for any green hotel—and Pürlin will offer tent cards for use in guestrooms to explain the advantages of the linens. “We believe that Pürlin bed linens will be viewed as an amenity by the guest,” Ferrell says.

‘There Must be a Better Way’

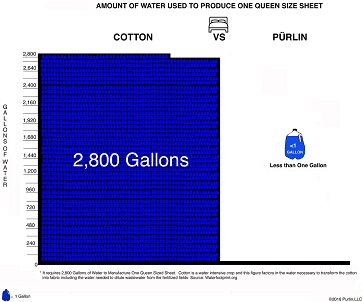

Several years ago, Ferrell attended a conference on water. “It really made me understand the global problems of water and heightened my concern for fresh water which is not a renewable resource,” he says. “I learned that it takes 2,800 gallons of water to make one queen-size cotton sheet.” He thought there must be a better way. Today, it takes less than one gallon of water to make a Pürlin sheet. Pürlin linens are delivered folded and ready to use, generating additional laundry savings.

Quality-wise, Ferrell says, “Our sheets are softer than most hotel sheets because they are spared from the grueling laundering process that hotel sheets must endure.”

Quality-wise, Ferrell says, “Our sheets are softer than most hotel sheets because they are spared from the grueling laundering process that hotel sheets must endure.”

Assuming the sheets and pillowcases account for 50 percent of the laundry load, a typical 300-room hotel requires 1.5 million to 1.7 million gallons of water per year to wash those linens, resulting in the creation of 1.5 million to 1.7 million gallons of wastewater. By eliminating 50 percent of the laundry load, Pürlin linens will reduce the costs that have been associated with laundering the bed linens i.e., labor, detergent and chemicals, water and wastewater, electricity, etc., and best of all it eliminates the expensive cost of bed linen replacement.

In a recent analysis done for the Las Vegas hotel market, if all 169,100 hotel rooms were using Pürlin linens, approximately 850 million gallons of water per year would be saved, thus eliminating the creation of 850 million gallons of waste-water per year.

Program Will Start in Orlando

Pürlin sheets and pillow cases are currently being tested in Florida and Pürlin is already fielding queries from hospitality and health care organizations in anticipation of their rapidly approaching midyear 2018 fulfillment schedule. The intention is to begin rolling out the program in central Florida. The Orlando market alone has approximately 115,000 hotel rooms, 20,000 time shares and 26,000 vacation home rentals, which when combined represent an estimated 385,250 beds. Thus, the potential demand from this market alone could justify the building of a Pürlin Closed-Loop Center in Orlando where the linens will be manufactured, distributed and recycled. Eventually, there will be regional Pürlin Closed-Loop Centers located throughout the United States.

The cost of using Pürlin will be at or below what a hotel typically spends for purchasing and maintaining bed linens. Because Pürlin linens are recycled after each use, the hotel owner will never have to replace damaged or worn linens again.

The cost of using Pürlin will be at or below what a hotel typically spends for purchasing and maintaining bed linens. Because Pürlin linens are recycled after each use, the hotel owner will never have to replace damaged or worn linens again.

After demonstrating Pürlin’s capacity to reduce water and wastewater, Ferrell’s team will begin working with local utilities and the USGBC-LEED program, encouraging them to offer incentives and enhanced credits to hotels that use Pürlin linens.

When asked if such a radical laundry shift will result in jobs lost, Ferrell said it will simply free up staff in the laundry room to do other housekeeping duties.

Like others in the lodging industry, Ferrell is passionate about what he describes as sustainable capitalism. “I am very environmentally conscious,” he says. “We have figured out a way to stop wasting fresh water, provide the guest with soft, hypoallergenic sheets, while simplifying the hotel laundering operation.”

Glenn Hasek can be reached at editor@greenlodgingnews.com.