It is quite astounding how many hotels are doing it and how much water and energy they are saving. What I am referring to is recycling laundry water using a system from AquaRecyle. I have been familiar with AquaRecycle for quite a few years and picked up some material about it at The Clean Show in Orlando in late August.

In 2024, Marriott International properties recycled 2 billion gallons of laundry water using AquaRecycle. Hilton Worldwide: 897 million gallons. Parks Hotels: 515 million gallons. Hyatt Hotels and Resorts: 496 million gallons. The list goes on and is very long.

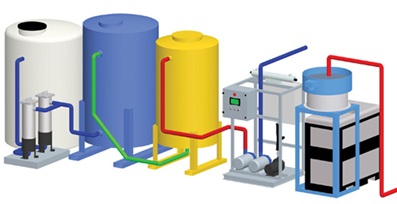

You can learn about each of AquaRecycle’s different systems here but I will highlight the overall benefits of AquaRecycle technology. First, AquaRecycle users can enjoy tremendous reductions in utility costs and achieve financial control by filtering and recycling all the laundry wastewater. Reduce water and sewer costs by 80 percent. Water usage is drastically reduced by reclaiming and treating 100 percent of the wastewater. Approximately 10 percent of the total water used in the wash process is lost through evaporation, and an additional 5 percent is used for backwashing the filters. The net amount of water recycled and sent back to the washing machines is 85 percent of the washing machine’s total water intake.

Using AquaRecycle, one can reduce energy costs by up to 50 percent because the recycled water is already pre-heated. In many laundry operations, the combination of high temperature hot water (160 to 180 degrees) with cold water rinses and flushes provides an average wastewater temperature of 110 to 120 degrees. This temperature is maintained throughout the closed loop, pressurized recycle process. Typical city water sources provide water at temperatures between 55 and 65 degrees. Recycled water only requires heating an additional 30 to 40 degrees to bring it to the desired wash temperature compared to an additional 100 degrees without the recycling system.

AquaRecycle customers can expect a payback on most systems in two years or less.

Say Hello to Mr. H.E.A.T.

If energy can be reused in washers, what about dryers? Through AquaRecycle, ThermalRecycle introduces its patented dryer-exhaust reuse technology Mr. H.E.A.T (Heat Exchange Air Transfer). The Mr. H.E.A.T. design fits virtually any commercial dryer, old or new. By using its proprietary Thermal Heat Wheel, the patented system captures the waste heat naturally discharged from dryers and recovers it to the incoming air for significant savings.

According to AquaRecycle, its many solutions advance customers’ corporate ESG sustainability goals by providing specific measurements of resource utilization along with financial savings and efficiency optimization.