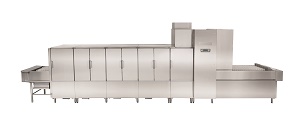

TROY, OHIO—Hobart’s FT1000 Advansys flight-type dish machine has been awarded the 2015 Kitchen Innovations Award, which recognizes foodservice equipment and technologies that improve kitchen operations and benefit restaurant operators. The FT1000 is going to be on display in booth 4031, as well as the Kitchen Innovations Pavilion, at the 2015 National Restaurant Association Show in Chicago, May 16 to 19.

TROY, OHIO—Hobart’s FT1000 Advansys flight-type dish machine has been awarded the 2015 Kitchen Innovations Award, which recognizes foodservice equipment and technologies that improve kitchen operations and benefit restaurant operators. The FT1000 is going to be on display in booth 4031, as well as the Kitchen Innovations Pavilion, at the 2015 National Restaurant Association Show in Chicago, May 16 to 19.

“In today’s market, with energy, water and labor costs on the rise, we know that our customers want and need a reliable dish machine that saves them time, energy and money,” said Megan Dyer, Product Line Manager for Hobart Warewash. “The Hobart FT1000 flight-type dish machine provides new and innovative technologies that deliver significant reductions in water, energy and chemical consumption for operational savings of up to $26,000 annually, and we’re honored to receive this year’s Kitchen Innovations Award.”

The Kitchen Innovations Awards, presented by the National Restaurant Association, recognize innovative foodservice equipment and technologies that address the issues and trends that are the most important to foodservice operators. This year’s innovations focused on topics related to water waste reduction, enhanced energy efficiency, increased safety and sanitation, space constraints and more.

Three Models Available

The Hobart FT1000, which comes in three models, is the industry’s first and only ventless flight-type in the marketplace. With features such as Ventless Technology, Automatic Soil Removal, Auto Clean and Auto Delime, the FT1000 boasts the industry’s lowest total cost of ownership.

• Ventless Technology enables the machine to operate without a direct vent connection and capture heat from the waste air to heat the machine’s wash tank, blower dryer and final rinse.

• Automatic Soil Removal (ASR) results in cleaner wash tanks and reduced tank refills per day, reduced chemical consumption, reduced labor and reduced pre-rinse water consumption, all without interrupting the wash cycle. Fine particles are contained in ASR’s dedicated wash tank, while larger particles are removed from the system to an external scrap basket.

• Auto Clean enables the machine to clean itself automatically, leading to increased operator productivity. Auto Delime creates a custom schedule, notifies operators when a cycle is required and can automatically complete the cycle, saving operators up to 50 minutes per cycle. It also automatically delimes the booster heater, and is the industry’s only flight-type with the ability to do so.

Go to Hobart.